Mechanical seal flushing thermosiphon systems are a vital component in ensuring the smooth and efficient operation of industrial machinery. These systems play a crucial role in maintaining the integrity of mechanical seals, which are essential for preventing leaks and ensuring the proper functioning of rotating equipment.

One of the key benefits of a mechanical seal flushing thermosiphon system is its ability to provide continuous and reliable cooling to the mechanical seal, which helps to prevent overheating and premature wear. This is especially important in high-temperature applications, where excessive heat can cause damage to the seal and impair the performance of the equipment.

Additionally, mechanical seal flushing thermosiphon systems help to flush out any contaminants or debris that may accumulate around the seal, reducing the risk of seal failure and extending the lifespan of the equipment. By maintaining clean and well-lubricated seals, these systems contribute to the overall efficiency and reliability of industrial machinery.

Furthermore, mechanical seal flushing thermosiphon systems are easy to install and require minimal maintenance, making them a cost-effective solution for businesses looking to improve the performance of their equipment. With regular monitoring and upkeep, these systems can help prevent costly downtime and repairs, ensuring that operations run smoothly and efficiently.

In conclusion, mechanical seal flushing thermosiphon systems are a valuable asset for businesses across various industries, providing consistent cooling and protection for mechanical seals. By investing in these systems, companies can safeguard their equipment, reduce maintenance costs, and enhance the overall productivity of their operations.

|

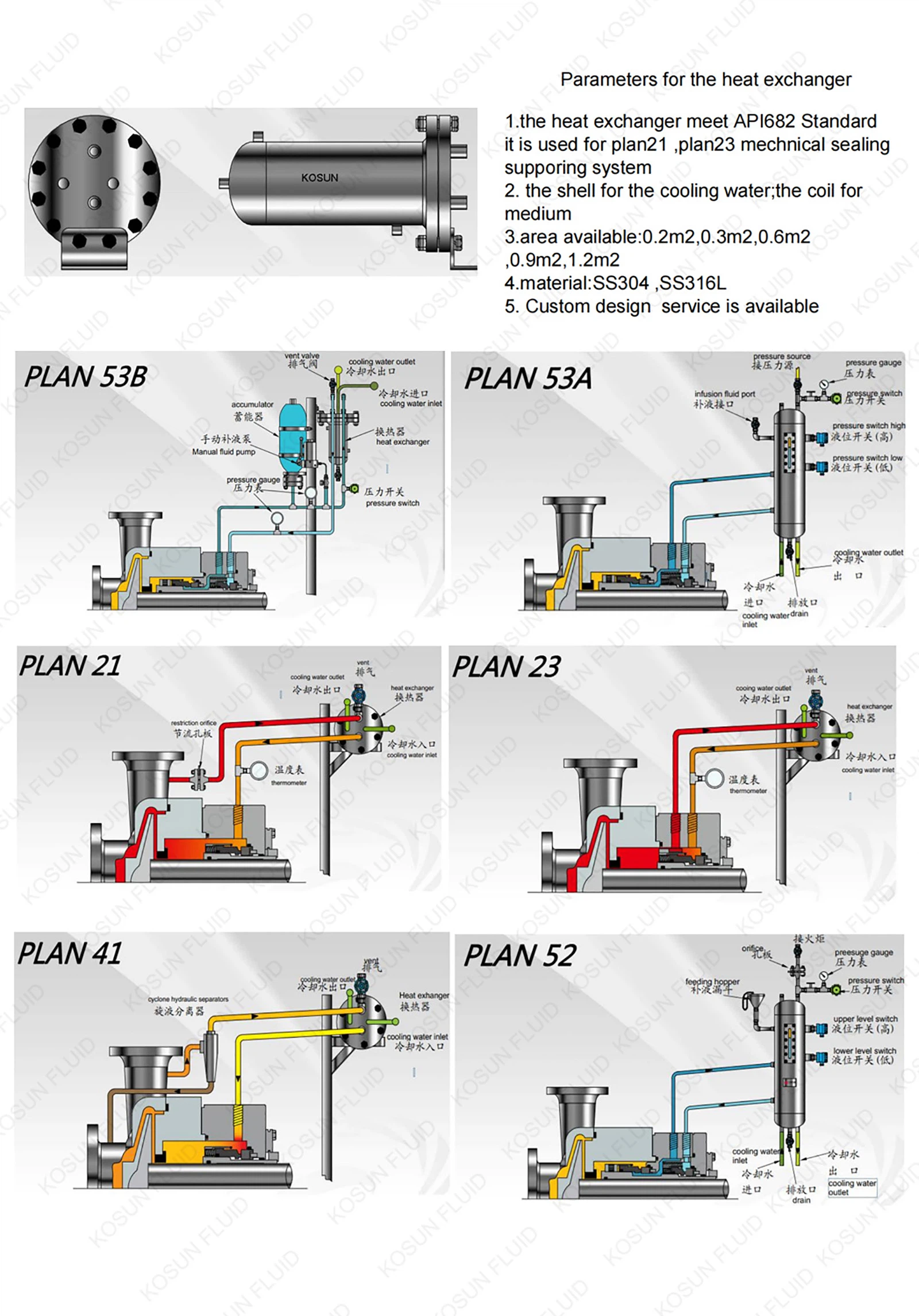

ITEM |

PARAMETERS |

|

Material |

SS304 ,SS316L |

|

Surface finish |

internal mirror polished ,external sand blasting |

|

Capacity |

9L ,12L ,20L |

|

Operate pressure |

70 Barg |

|

Operate temperature |

-40DegC to 300 DegC |

Hot Tags: api plan 52 53 mechanical seal flushing thermosiphon system, manufacturers, sanitary, stainless steel, food grade